PRINTING - DECORATING MACHINES

PRINTING - DECORATING MACHINES |

|

PRODUCTS TO USE

- Printing screen frame,

printing size mm. 500x700

- U.V. clear resin

- Metalized hot stamping foil

PRINTABLE SURFACES

- Smooth and row paper

- Rigid and flexible plastic

- Textil - Leather

- Wood - Metals Glass

- Dimension: mm. 1250x4500

- Total weight: Kg 1200

- Air consumption: 150L/min

- Power voltage [gold printer] 400V-50Hz

- Power voltage [u.v. printer] 400V-50Hz-10/30A

- The Machine must be connected to aspiration system

|

|

Metall-Foil S.p.a., since 1989, is a manufacturer of slitting machines specialised in cutting and rewindinh Hot Stamping Foil, Metallized Films in various thickness, and Thermal Tranfer Ribbons 4,5 microns. [more...]

Slitter for THERMAL TRANSFER RIBBONS

Slitter for THERMAL TRANSFER RIBBONS |

|

- Maximum jumbo width : mm 1.000

- Maximum rewinding speed : mtl/min. 300

- Automatic speed-control during START/STOP phases

- Main jumbo maximum Ø: mm 600-mtl 20.000

- Two rewinding turrets with twin shaft 1" (1/2" optional)

- Switch rewinding film (IN/OUT)

- Setting and control devices for film tension

- Razor grid connected to the balancing system

- Edge-guider with I.R. reading (optional)

- Two antistatic bars

- Edge rewinders

- Curved expander-roller to eliminate folds

|

|

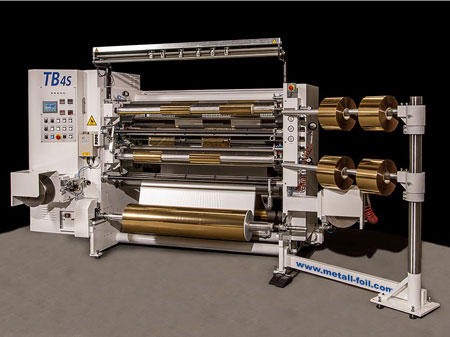

Slitting rewinding machine high sensitivity

Slitting rewinding machine high sensitivity |

|

- Maximum width of the film: mm1650 net

- Maximumrewinding speed: lmt. 300/min

- Film carrying controlled by a central calender

- Main Jumbo maximum Ø mm. 800 = lmt. 10.000 (12 micron)

- Pneumatic shaft for starting jumbos Ø 3" e Ø 6"

- Two rewinding shafts Ø 1"

- Two rewinding shafts Ø 3"

- Anti-vibration devices for shaft Ø 1"

- Two rewinding durectorions (IN and OUT)

- Automatic adjustament of film tension during unwinding and rewinding

- Disk brake for tension control of the jumbo

- "Gap Rewinding" disposal equipped with digital pannel

- Carring blades shaft controlled by a balancing system

- Razor-blades cutting system for thin films

- Circular blades cutting system for high thickness films or paper

- Line up device with infra-red chip (optional)

- Anti-static bars

- Edge-rewinders

- Curved expander-roller to eliminate folds

|

|

|

![]()